SZ CnAuto automation equipment Co., Ltd.

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

作者:馬交易???日期:2019-08-24 19:45???瀏覽:

What is the requirement of dispensing process at the bottom of dispensing machine?

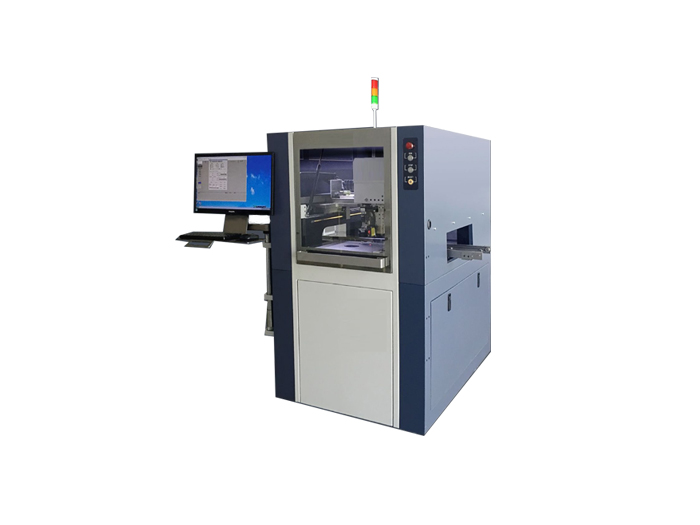

What is the requirement of dispensing process at the bottom of dispensing machine? Thirdly, the bottom filling process has a high demand for dispensing accuracy, especially when the RF shield cover is assembled in place, a requirement that can only be achieved through visual dispensing machine operation on the upper surface.

Thirdly, the bottom filling process has a high demand for dispensing accuracy, especially when the RF shield cover is assembled in place, a requirement that can only be achieved through visual dispensing machine operation on the upper surface.